Nothing audio related to see here. Just an afternoon rant…

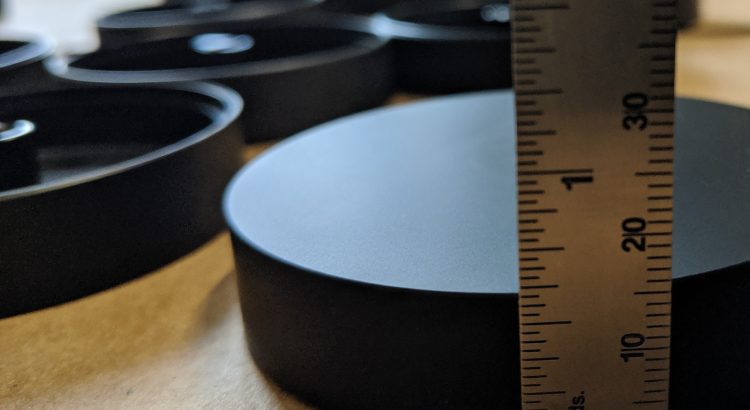

One of our production technicians pulled me aside last week to say, “Hey, uhm, these knobs are not looking so good. Most are scratched.”

Following a week of delays from a winter storm, our team had been looking forward to this batch of knobs to fill pallets with orders to our retailers in Europe and Asia.

Our head Q/C technician spent the morning inspecting. A good batch of aluminum parts yields over 95% usable pieces. This batch of knobs was about 40% successful.

We immediately updated Shipping Time on impacted products and emailed customers with photos and two options: Wait patiently for the next batch, or accept a discount for immediate shipment.

On the business side, we emailed pictures to the responsible supplier. The owner called back within the hour. . .

How We Plan

We’re proactive. JDS Labs’s success and reputation—aside from building world leading amplifiers and DACs—is tied to our custom ERP system. Every support request is one or two clicks away. Our inventory needs are automatically recalculated as orders come in. A single click displays a high level inventory forecast, with one more click to render product or component level trend lines. Data is at our fingertips, so we see inventory crunches months in advance.

When AKM’s factory burned down in October 2020, I was at ease. I shrugged and pondered implications calmly over the weekend. We’d planned production for a minimum of 6 months. Even with high demand, we had adequate chips on the shelf to survive the IC famine. Of course, we have backup plan B’s and plan C’s in place.

When suppliers fail us, we are prepared. Usually.

Supply Chain Weakness

A single person in a small company can carry a heavy load. Our local anodizer is one such small company, generally turning around orders within 1 week while meeting our stringent Q/C requirements. While rarely perfect, they had earned our trust by delivering 95% acceptable parts in recent years. The remaining 5% have been discounted as B-Stock. We keep suppliers local where possible to reduce material transit time and enable rapid manufacturing feedback.

Unbeknown to us, the top anodizing manager departed the company while February’s batch of knobs was in process. Delivery time doubled, and we were shocked to see an unacceptable drop in quality. This person had a huge impact on their success.

This is not to place blame. Suppliers are made of people, and people make mistakes. The weakest link in our supply chain is our responsibility and we remain accountable. We have redundancy in place for machining, PCB manufacturing and assembly, and material sourcing. But we had no redundancy in anodizing based on the level of established trust, and the greater relative risk of using multiple anodizers (i.e., differences in finish color). The real mistake was ours: we had been operating with an inadequate inventory buffer.

As frustrating as it was to see weeks of work potentially destroyed, we knew it was better to communicate delays and deliver our best work. Most customers understood our concern–thank you!

What Happened: Our anodizing partner was quick to listen, apologize, and fortunately fix the blemished knobs (scratches were only at the anodize layer). They took corrective action internally and shared that a new employee had carelessly stacked our knobs in final packaging. This came down to being short-staffed.

Adapting to Change

We believe in continuous improvement.

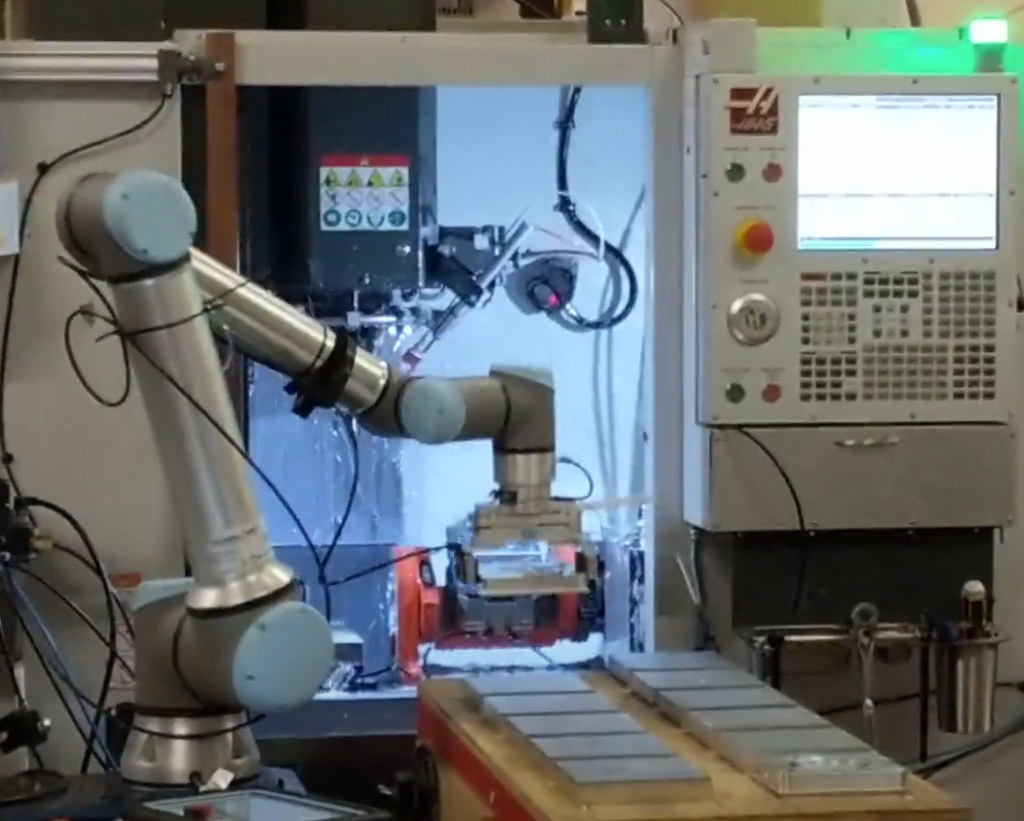

At the onset of the global pandemic, we were down to a skeleton crew for safety. I found myself alone in our machine shop each morning and evening, loading blocks of aluminum into vices and pressing green Start buttons to squeeze in extra machining hours, beyond what our CNC operator could provide. The time absolutely flew by while I balanced daily responsibilities, machined parts, and helped our head of production with his massive workload. My R&D hat, so to speak, was on the shelf in summer 2020.

Working 12 hour days is not leadership. It’s unsustainable and destructive in the long-term. It drains the body of sleep, health, and sanity, and robs a company of its creativity. I responded to last year’s crisis by observing firsthand the major inefficiencies and weaknesses in our operations. Just-in-time deliveries were falling apart and we had only ¼ of the labor we needed.

Understanding the need for change and pushing for constant improvement leads to success. In a matter of months, we retooled the entire machine shop. Every 3-axis machine was replaced with 4-axis machines paired with a dedicated robot. We more than doubled productivity while cutting human labor to minimal levels.

It was a pleasant surprise when I heard the machines humming one evening, and realized my Subaru was the only vehicle in the parking lot. Nick was watching from home in St. Louis. We had achieved autonomy.

Agility

I must give credit where due. Our ability to move fast is not my doing; it’s the direct result of Nick’s vision of automated manufacturing. We are agile today because of his dedication to automation. The robots paid off again last week. In only three days, we had anodized parts in hand from two of our preferred, less local anodizing partners. This speed is near impossible when relying on contract manufacturers.

Looking Ahead

Last week’s anodizing mess turned out to be a healthy reminder to think far ahead and mitigate weaknesses.

Most of our anodizing will be transitioned from STL to Chicago in March, and we expect to achieve doubled anodized inventory by next month.

We’re excited to improve quality and increase stock levels of Element II, EL Amp II, and EL DAC II , especially to our EU retailers.